Boost your team's skills and your budget! Enjoy group discounts for collaborative learning. Send an inquiry to info@peassociations.com.

Principles & Application of Production Logging Tools (PLT) (Industry Software Applications)

Description

Production logging is a suite of logging measurements in either production or injection wells to evaluate well or reservoir flow performance. Special-purpose production logging tools can evaluate the well completion or look behind the pipe to evaluate the formation and its fluids in the near-wellbore vicinity. Production logs are playing an increasing role in modern reservoir management by providing the only means of directly identifying downhole fluid movement. Cased hole logs can be run with the purpose of evaluating the tubular and cement integrity, quantifying fluid inflows/outflows, determining the formation saturation, etc. Each PL measurement has limitations, specific running procedures, and interpretation methodology. Cased hole logging tools are used to efficiently and accurately evaluate the well’s performance. They diagnose and verify potential issues in reservoir performance. Water identification and fluid movement in both injection and producing wells are evaluated using spinners, tracers, pulsed neutron oxygen activation, temperature, and noise surveys. A variety of fluid identification sensors are used to evaluate multiphase flow. These tools together are used to quantify the sources of water, oil, and gas production, and are critical to the control of excessive water or other phases. Inflow Performance Relationships (IPR) are determined for individual downhole zones.

Who Should Attend:

Petroleum Engineers

Reservoir Engineers

Production Engineers and Technologists

Well Testing Field Engineers

Well Testing Field Specialists

Petrophysicists

Well Logging Analysts

Ways & Means:

Interactive sessions and exercises

Hands-on experience examples

Workshop using real field cases

Software practice

Why You Should Attend:

By the end of this course, you will be able to:

Understand the concepts and techniques of production logging tools

understand the principle, acquisition, and limitations of these measurements, and will also be able to perform a quality check and basic interpretation of the different tools.

Measure zonal inflows in producing wells using temperature measurements

Measure multi-phase flow using temperature, spinner (flowmeter), and fluid holdup measurements

Define injection profiles using temperature and spinner (flowmeter) measurements

Identify flow behind the pipe with temperature or noise logs

Interpret cement bond logs and ultrasonic logs to determine cement quality

Measure flow inside and outside casing with pulsed neutron tools

Apply specialty tools (array holdup and spinners and pulsed neutron tools) for flow profiling in high-angle/horizontal wells

Confirm the location of some types of completion components using pulsed neutron measurements

Refine well profiling and optimize well intervention

Design a logging program using the appropriate production logging services for well diagnosis and reservoir surveillance

Quality check PLT data and generate a model interpretation

Day 1:

• Overview of the production system

• Well Completions and its effects on production logging:

• Open Hole completions

• Casing, Liners, and Gravel Pack

• Perforation techniques

• Casing-guns perforations

• Through-tubing perforations

• Tubing-conveyed perforations

• Cased hole formation evaluation

• The cased hole logging environment

• Cement evaluation tools (CBL, VDL, CCL, IBC, USIT, etc.)

• Logging techniques for vertical, deviated and horizontal wells

• Depth Control in Cased Hole

Day 2

• Applications of production logging tools (PLT)

• Diagnostic of the production problems

• Productivity Index (PI), inflow performance, zonal production

• Two and three-phase flow calculations

• Inflow performance and productivity index for oil wells and gas wells

• Outflow performance: matching inflow with outflow to optimize well productivity

• Flow regimes in vertical and deviated wells and slippage velocities

• Flow regimes effects on the 3-phase flow

• Inter-zone crossflow

• Flowmeter response and quality control

• Reservoir Fluids (PVT) properties and PVT correlations

• Reservoir drive mechanisms and associated production problems

• Meaning of production logging and its basic downhole string.

• Define and estimate the 3-fluid phase velocities

• Production logging in vertical/deviated/horizontal wells

• Cross-flow identifications and remedial actions

• Evaluating deviated and horizontal wells

• Effects of deviation on spinner response and slip velocity

Day 3

• PLT tools categories

• Spinners or Flowmeters (Fullbore, Continuous, Inline, and Diverter)

• Flow evaluation using spinners

• Fluid identification logs for multiphase flow

• Holdup, cut, and slip velocity

• Density Gradiomanometer

• Capacitance tool

• Pulsed Neutron Logging (PNL) tool

• Spinners, inline and full-bore measurements

• Measurements of three-phase holdups

• Slippage velocities: theory and empirical charts applications

• Fluid velocities techniques:

• Spinners: inline spinner, full-bore spinner, and micro-spinner

• Oxygen activation to measure water velocity

• Gas bubble velocity from the optical sensor (GHOST)

• Spinner threshold:

• Measuring Vth in a stationary fluid

• Measuring Vth under flowing conditions

• Applications to detect leaks

• Tool calibration and logging data measurement

• Depth control in cased hole wells using GR and CCL

• Conservation of momentum equation to define the spinner velocity

Day 4

• Cement evaluation logs and ultrasonic tools

• Ultrasonic imaging logs

• Temperature logs

• Fluid holdup logs (gamma density, capacitance, differential pressure)

• Pulsed neutron spectroscopy logs

• Multiphase flow and slip velocity

• Effects of hole deviation on fluid holdup and multiphase flow velocities

• Combining production logs for multiphase flow profiling

• Corrosion monitoring

Day 5

• Leak detection using temperature log

• Temperature and noise logging

• Detection of water flow using oxygen activation

• Reservoir saturation tools and their application

• Integration of spinner reading and fluid identification devices reading to get flow profile

• Distributed temperature sensing (DTS)

Day 6

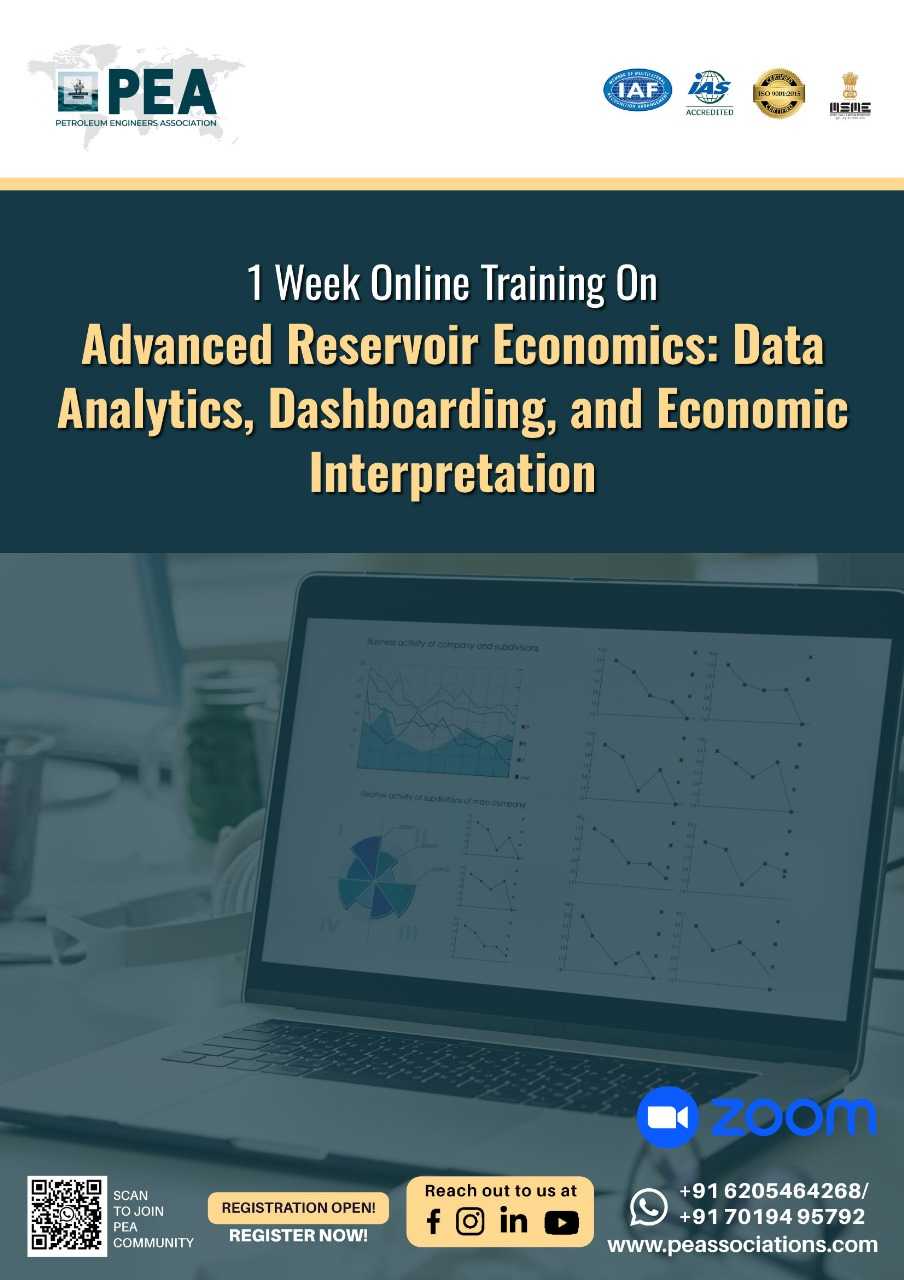

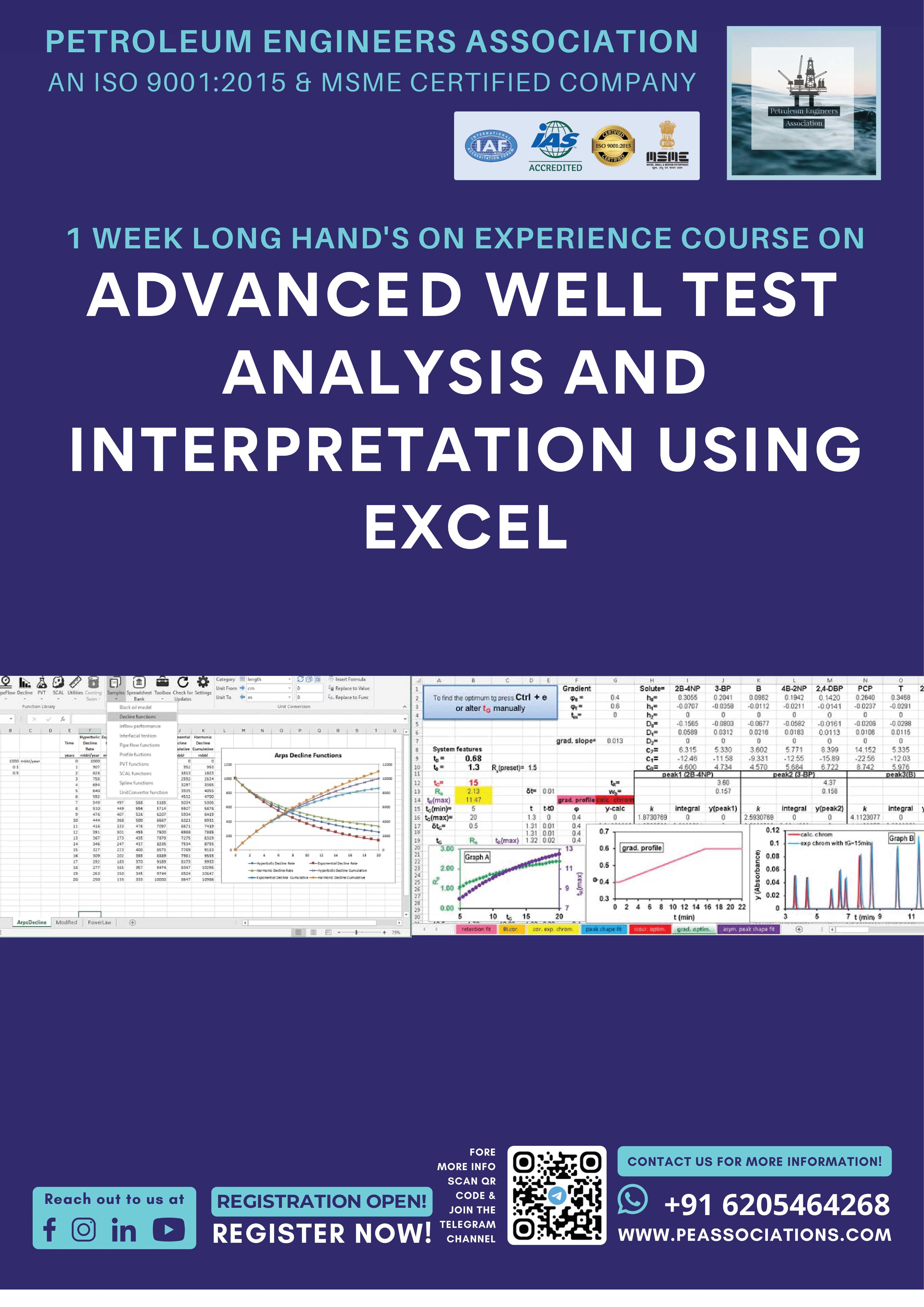

• Overview of software applications

• Conventional Workflow

• Two-Phase Interpretation

• PLT data interpretation

• Calibrate: spinner calibration

• V apparent: calculation of an apparent velocity log

• PVT: definition/editing of the PVT model, selection of correlations

• Zone Rates: calculation of rates on the zones defined by the option above

• Log: generation of rate logs, schematic (rates and/or ratios), or complete

• Time Lapse: time-lapse tracks for the schematic production profiles

• Three-Phase Interpretation

Day 7

• Pulsed Neutron Logging (PNL)

• Create a PNL interpretation

• Crossplots for each defined PNL zone

• Generates the calculated formation water saturation.

• Apply sigma logs, GR, water saturation, temperature or pressure.

• Challenges in horizontal and highly deviated wells

• Advanced PLT sensors

• Selective Inflow Performance (SIP)

• IPR Computations

• IPR Types

• Pressure or Pseudo-pressure

• Datum Pressure Correction

Day 8

• Advanced Workflow

• Formation Testers (MDT, XPT, RDT, etc.)

• Assigning a label and status

• Plotting

• Gradients and contacts

Day 9

• Designing a production logging program for problem identification and solution

• PLT job planning

• Basic PLT string

• PLT deployment

• PLT string running procedure

Day 10

• Case Studies

• Software applications

• Major challenges in PLT interpretation