Boost your team's skills and your budget! Enjoy group discounts for collaborative learning. Send an inquiry to info@peassociations.com.

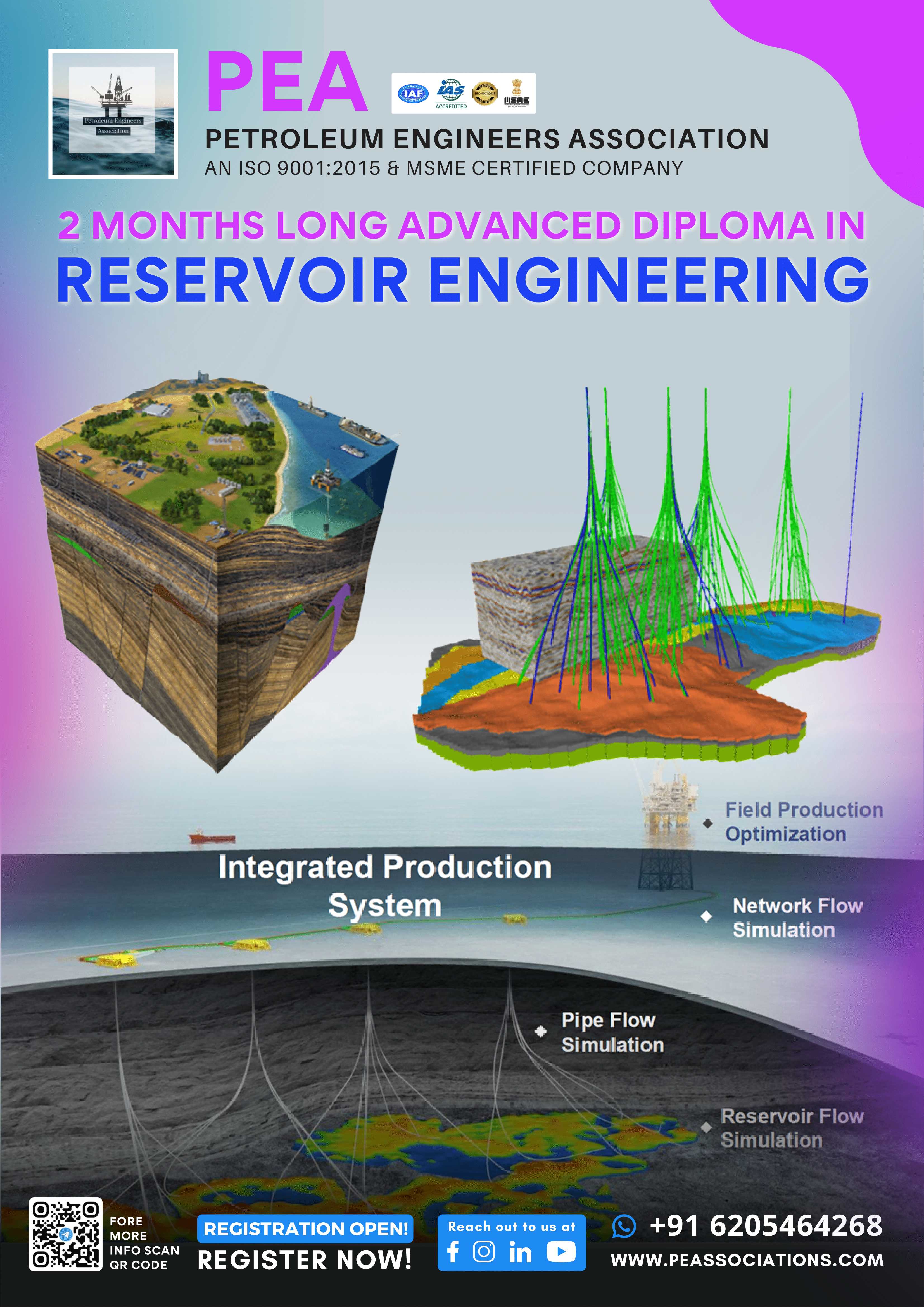

Integrated Production Modeling and Optimization

Description

This

provides an extensive and practical knowledge for understanding of the concepts

and practical applications of full field modelling including reservoir, pipe,

and surface network flow simulations. Analysis of the reservoir component is

critical for identifying the original resources (STOIIP and GIIP) and

understanding the main reservoir driving energies and mechanisms. Additionally,

reservoir modelling with material balance analysis can predict full field

performance. At the bottomhole terminal, the system must be solved for

appropriate operating point using inflow and outflow models. Recently, several

inflow and outflow models can be applied based on the field type and the

operating conditions. At surface, analysis of the production systems is

important for optimizing the field performance and maximizing the revenues.

Integrated network modeling offers this opportunity by full system analysis and

predict the possible bottlenecks. Accordingly, actions can be applied for

optimization and improvement. Network and field performance covers the

interactions of wells and pipelines and optimization of oil or gas flowrates

subject to constraints. When linked to reservoir models, the network model

becomes predictive with time allowing forecasting of production profiles,

timing changes of production and injection wells etc.

Integrated Production Modeling (IPM) is essential for optimizing the performance of oil and gas fields. In this course, participants will learn to seamlessly integrate reservoir, well, and surface facility modeling to enhance productivity. Leveraging industry-leading tools—MBAL for reservoir modeling, Prosper for well performance, and GAP for surface facilities—participants will develop a holistic approach to optimize production.

·

Explain the principles of reservoir fluid

composition, properties and modelling.

·

Explain the principle and limitations of the

material balance method and the influence of drive mechanisms on the recovery

factor

·

Build a material balance model for a new oil

field development

·

Evaluate the range of possible inflow and

outflow performance relationships for wells.

·

Applying the nodal analysis to predict well

performance and the effect of artificial lift

·

Build, validate, and match a naturally flowing

oil well model

·

Apply and interpret more complex inflow

modelling options

·

Run nodal analysis sensitivities, interpret the

results and export lift curves.

·

Perform history matching and run production

forecasts

·

Run a full field model with production

forecasting including producers and injectors

·

Analyze and optimize the surface production and

injection networks

·

Demonstrate proficiency in the use of production

optimization and modelling software

The course combines lectures, real-world case studies, and interactive hands-on sessions with IPM software. Each participant will work on exercises using MBAL, Prosper, and GAP, allowing them to gain practical experience under the guidance of industry experts.

·

Reservoir Engineers

·

Petroleum Engineers

·

Production Engineers

·

Field Engineers

·

Processing Engineers

Day 1

·

Reservoir fluid and rock systems

·

Integrated production system

·

Field development stages

·

Overall system approach

·

Methodology of pressure

loss in the wellbore

·

Importance of PVT data for

integrated production system analysis

·

Inflow performance models

Day 2

·

Reservoir to surface integrated modeling and

optimization

·

Material balance Theory

and applications

·

Material balance for oil reservoirs

·

Material balance for oil reservoirs (solving for

oil in place and aquifer size)

·

Summary of drive mechanisms as applied to

material balance

·

Linear form of MBE (Havlena & Odeh approach)

·

Straight-line analysis techniques

·

Analytical and graphical tools

·

Drive indices and energy plots

·

Dake & Campbell diagnostic plots, their

applications

·

Using material balance models for prediction

·

Analytical aquifer models – concepts

·

History

matching techniques (analytical and graphical)

Day 3

·

Material balance model:

·

PVT data and tank parameters

·

Aquifer models and rel-perms

·

Water influx models

·

Production and reservoir history

·

Prediction of reservoir performance

·

STOOIP calculation using Monte Carlo

·

Decline curve analysis - history matching and

prediction

·

Waterflood analysis with Buckley Leverett 1D

model

·

Simulation & Running a prediction

Day 4

·

Building a wellbore model

·

VLP flow correlations theory

·

Matching

PVT and flow correlations

·

Nodal analysis

·

IPR and skin models

·

Defining and matching well testing data

·

Flow regimes of the vertical and horizontal

pipes

·

Defining and matching the VLP model

·

Running sensitivities

·

Generation lift curves

Day 5

·

Importing VLPs and IPRs

·

Defining system constraints

·

Multi‐tank and multi‐PVT

·

Field development example

·

Well development schedule top meet target production profile

·

Well inflow models of horizontal, vertical,

deviated, multilayer and multilateral geometries

Day 6

·

Nodal Analysis calculations

·

Re-perforation studies, analysis of skin, the

application of sand control

·

Sensitivity analysis and prediction

·

Multiphase pressure drop models

·

Assessing the productivity of oil, gas and

condensate wells

Day 7

·

Flow assurance studies

·

Hydraulic investigations can be conducted on

flow regimes

·

Erosional velocities, superficial velocities,

and slug catcher sizing

·

Thermodynamic calculations can include studies

on hydrate formation, waxing, and salt precipitation

·

Hydrate and scale inhibition

Day 8

·

Multiphase network modeling and optimization

·

Integrated analysis for production and injection

networks

·

Field development planning, testing various

strategies, and forecasting

·

Prediction using a fixed oil rate

·

Prediction using a well model

·

Building a new oil reservoir model - optimizing

the production profile

·

Full field development planning

·

Assigning production constrains

·

Solving for the entire production network

·

Defining rule-based constrains

·

Case studies and field examples

On successful completion of this training course, PEA Certificate will be awarded to the delegates

Hesham Mokhtar is a Reservoir Engineering Team Leader at General Petroleum Company (GPC) in Egypt. He has extensive experience in reservoir management, characterization, and production optimization. He is skilled in using various software for reservoir simulation and analysis. He has also delivered training courses on waterflooding, PVT analysis, reservoir simulation, and more.

- 14+ years of Petroleum Engineering expertise delivering technical solutions to E&P portfolios.

- Expert in reservoir evaluations, log interpretations, and hydrocarbon estimations using tools like Techlog, Volumetric, DCA, MBE, OFM, and KAPPA

- Analyzes production data, material balance, RFT/MDT data, and pressure transients for reservoir performance and optimization.