Boost your team's skills and your budget! Enjoy group discounts for collaborative learning. Send an inquiry to info@peassociations.com.

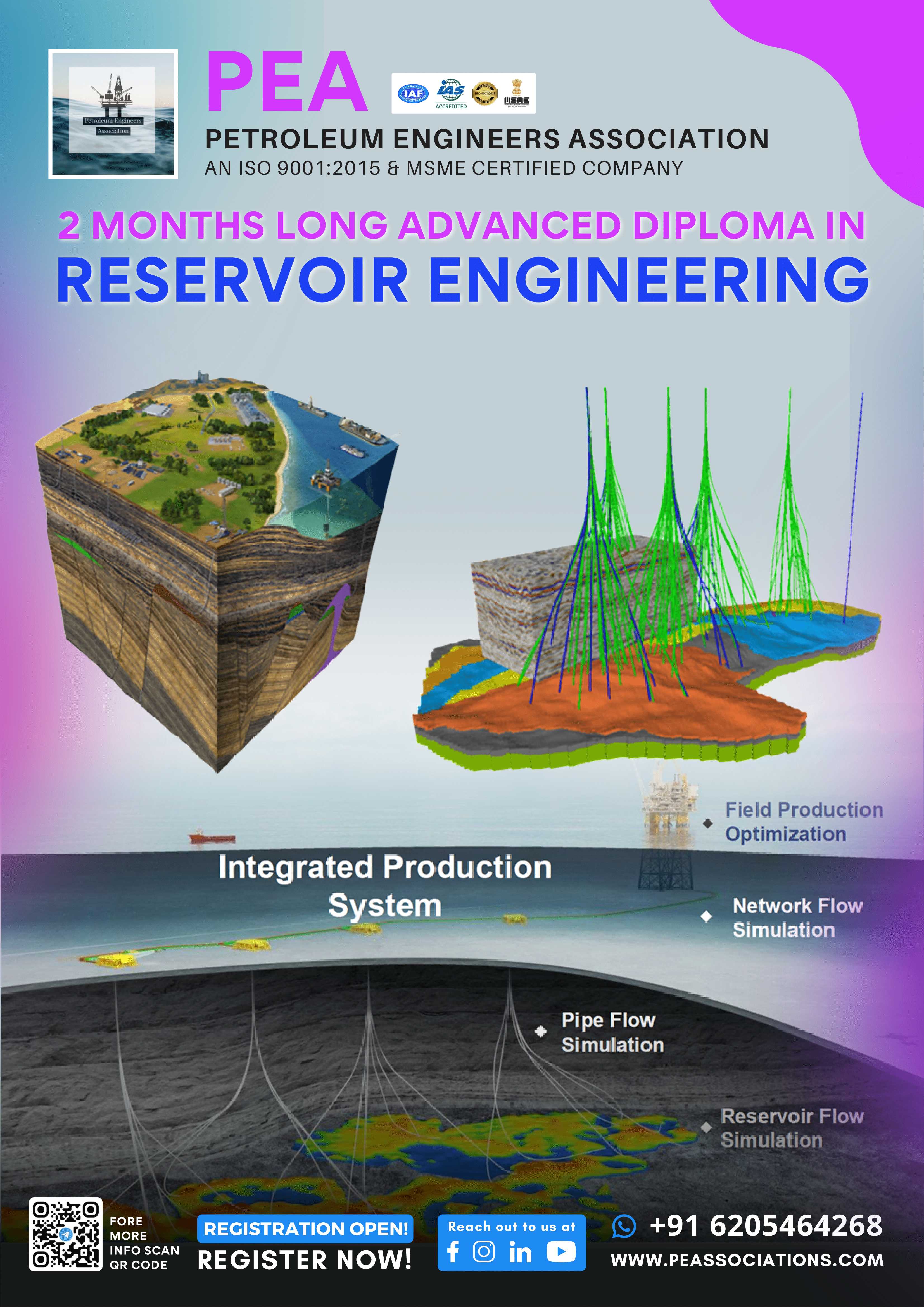

Integrated Reservoir Management

This course provides an in-depth understanding of Integrated Reservoir Management (IRM), focusing on strategies and tools to optimize reservoir performance. Learn how to collaborate effectively across disciplines, make data-driven decisions, and implement advanced techniques for sustainable reservoir management.

Description

Reservoir

management is an on-going, dynamic process of collecting, analyzing,

validating, and integrating reservoir description data and performance data

into an optimal reservoir development and depletion plan. This course will introduce a practical view

for reservoir management applications like reservoir evaluation and simulation,

production forecasting, material balance calculations, Monte Carlo simulation

analysis for reserve estimation, decline curve analysis, and waterflooding

design. The course will highlight the theoretical background and the practical

application. The course progresses from the measurement fundamentals to the

essential evaluation and assessment of the results and onto the practical

application in example studies.

Integrated Reservoir Management is essential for maximizing asset value and enhancing operational efficiency in complex reservoir settings. This course provides a comprehensive overview of IRM principles, including collaboration across multiple disciplines, reservoir monitoring, and data integration. Participants will gain insights into best practices, new technologies, and analytical techniques necessary for effective reservoir management in today’s dynamic oil and gas landscape.

· Model the reservoir through MBE tool assuming several scenarios for history matching and prediction.

·

Use well model (IPR & VLP) through the MBE

calculations to enhance the prediction accuracy

·

Monitor fluid contacts (OWC & GOC) to have a

deeper insight for reservoir management and surveillance.

·

Design the field development plan (FDP) for a

new field.

·

Model multiple juxtaposed connected reservoirs

and transmissibility estimation between them.

·

Calculate the original hydrocarbon in place

·

Predict reservoir or well production and

determine asset lifetime.

·

Design waterflooding project according to

reservoir properties and predict production performance

·

Prepare integrated studies for reservoir

characterization, evaluation and production prediction based on various

scenarios according to the included parameters

The course will employ a mix of interactive lectures, hands-on exercises, case studies, and group discussions. Real-life examples will illustrate concepts, allowing participants to apply what they learn to actual reservoir challenges. The training is designed to foster practical, collaborative problem-solving skills essential for modern reservoir management.

Reservoir Engineers

Petroleum Engineers

Production Engineers

Day 1: Introduction

· Introduction

· Oil Recovery Processes

& Full Field Modeling

· Role of Reservoir Rocks

& Fluids in Reservoir Management

· Oilfield Lifetime &

Development

· Typical Production

Performance

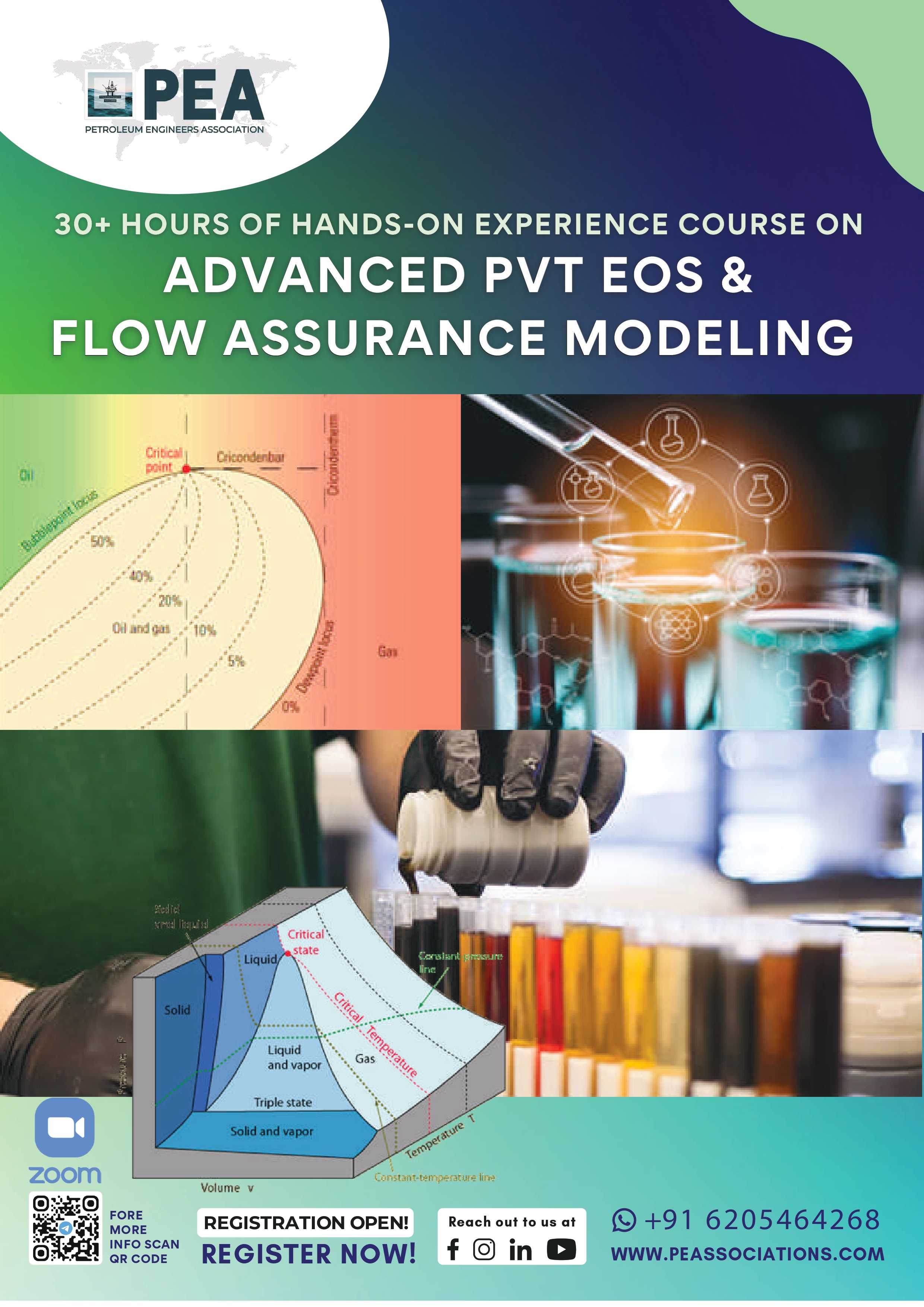

Day 2: Applications of Core & PVT Data

· Core Analysis Flowchart

· Conventional Core

Analysis

· Flow Units and Rock

Typing

· Relative Permeability

& Capillary Pressure Data

· Applications of Reservoir

Fluid Data

· PVT Analysis Workflow

in the Reservoir Management Process

Day 3: Formation Evaluation & Well Logging

· Formation Evaluation

Overview

· Wireline Logging

Operations

· Basic Concepts of Log

Analysis

· Open hole Logging

Measurements

· Integrated Formation

Evaluation Plan

Day 4: Hydrocarbon In-place & Reserve Estimation

· Why Reserve Estimates?

· Petroleum Resource

Management System: PRMS

· Reserves Estimation Techniques: Deterministic vs. Probabilistic Techniques

Day 5: Decline Curve Analysis (DCA) & Production Forecasting

· Performance-based

Reserve Estimates

· Reservoir Driving

Mechanisms & Production Characteristics

· Applications of Decline

Curve Analysis

· Conventional Decline

Curve Analysis (Arps’ Approach) & Assumptions)

· Advanced Decline Curve

Analysis (Fetkovich Approach) & Pitfalls

Day 6: Material Balance Analysis

· Material Balance

Analysis: Concept and General Form

· Havlena-Odeh Approach:

Approach, Typical Analysis Techniques, Dake & Campbell Diagnostic Plots,

Pitfalls, Case Studies

· Input data collection

and QAQC

· History Matching and

Reservoir Performance Prediction

· Better Reservoir

Performance Prediction Using Well Model

Day 7: Material Balance Applications

· Field Development Plan

(FDP)

· Monitor Fluid Contacts

(OWC & GOC)

· Determine Asset

Lifetime

· Monte Carlo Simulation

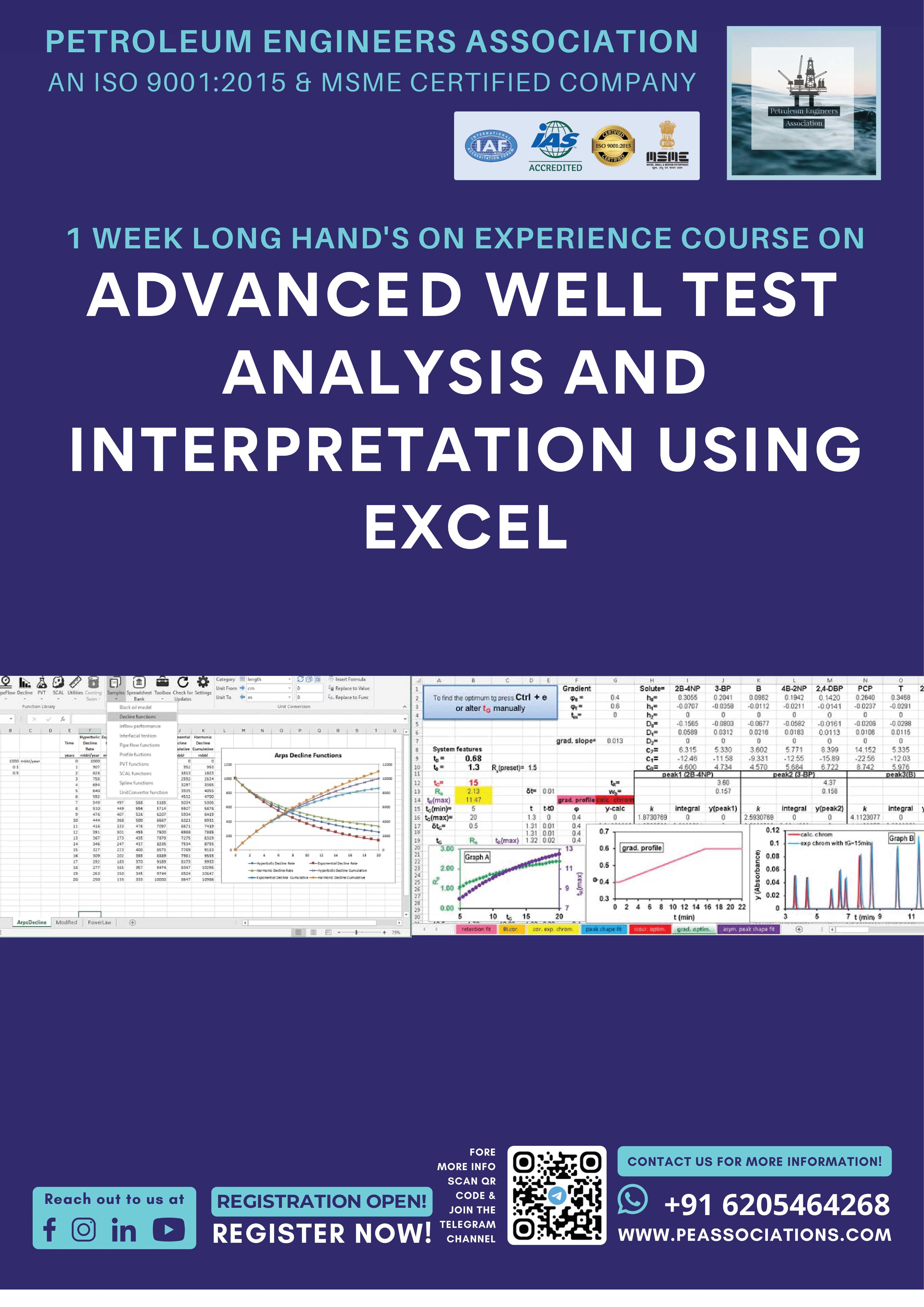

Day 8: Well Testing Analysis

· Role of Well Testing in

Reservoir Management

· Surface Testing

Facilities

· Types of Pressure

Testing

· Basic Theory &

Diffusivity Equation

· Type Curve Matching and

Pressure Derivative

· Reservoir Modeling

Using the Pressure Transient

· Well Testing

Interpretation Process

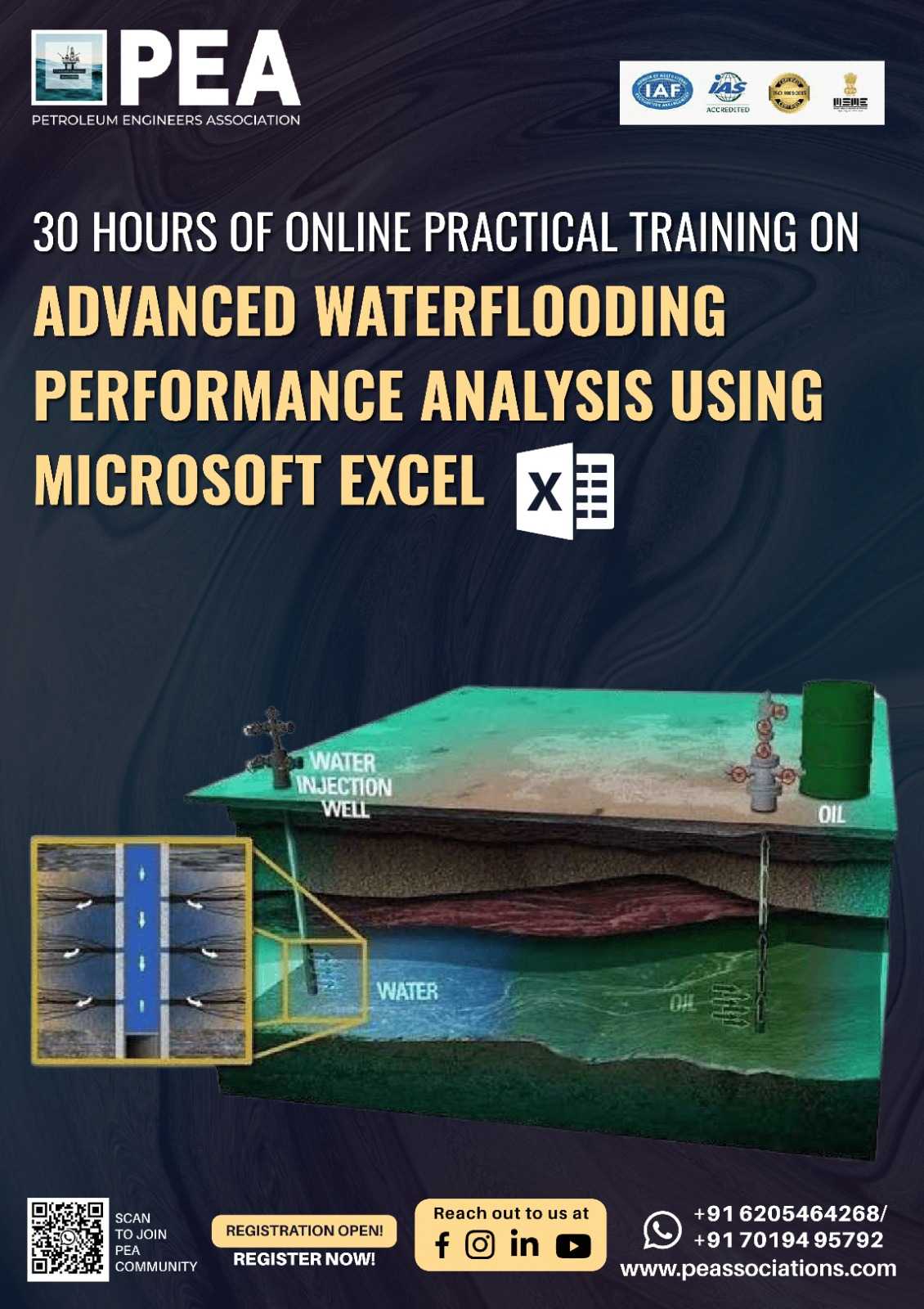

Day 9: Waterflooding Design

· Principles and

Applications of Waterflooding

· Voidage Replacement

& Fractional Flow Equation

· Analytical Methods for

Waterflooding Design and Performance Prediction

· Displacement Efficiency

Calculations

· Managing and Optimizing

Water Injection

Day 10: Modeling Applications for Reservoir Management

· Reservoir Simulation

Overview, Workflow, and Benefits

· Reservoir Model

Initialization

· Making a Development

Strategy

· Defining a Simulation

Case

On successful completion of this training course, PEA Certificate will be awarded to the delegates

Hesham Mokhtar is a Reservoir Engineering Team Leader at General Petroleum Company (GPC) in Egypt. He has extensive experience in reservoir management, characterization, and production optimization. He is skilled in using various software for reservoir simulation and analysis. He has also delivered training courses on waterflooding, PVT analysis, reservoir simulation, and more.

- 14+ years of Petroleum Engineering expertise delivering technical solutions to E&P portfolios.

- Expert in reservoir evaluations, log interpretations, and hydrocarbon estimations using tools like Techlog, Volumetric, DCA, MBE, OFM, and KAPPA

- Analyzes production data, material balance, RFT/MDT data, and pressure transients for reservoir performance and optimization.