Principles of Applied Flow Assurance

| Code | Date | Time | Duration | Location | Currency | Team of 10 Per Person | Team of 7 Per Person | Early Bird Fee Per Person | Normal Fee Per Person |

|---|---|---|---|---|---|---|---|---|---|

| PEA-PFA26 | 07 - 25 Sep 2026 | 9:30 PM Indian Time |

3 Hours Per Day

|

Zoom Online

|

USD

|

2000

|

2250

|

2500

|

3500

|

The classes will be via zoom online from monday to friday with 2 hours / day.

Boost your team's skills and your budget! Enjoy group discounts for collaborative learning. Send an inquiry to info@peassociations.com.

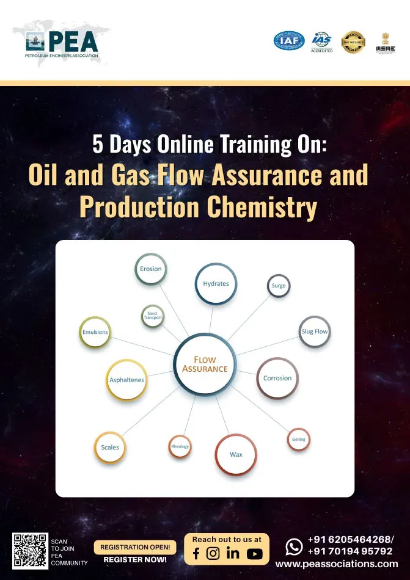

Principles of Applied Flow Assurance

This course provides a practical understanding of flow assurance fundamentals and their application in real-world oil and gas operations. Participants will learn to identify, analyze, and mitigate flow-related challenges such as hydrates, wax, asphaltenes, emulsions, and scale—ensuring uninterrupted production and cost-effective field performance.

Description

The Principles of Applied Flow Assurance course offers a comprehensive overview of the key concepts, mechanisms, and technologies that govern the transport of hydrocarbons from the reservoir to surface facilities. Flow assurance plays a vital role in maintaining production efficiency, minimizing downtime, and reducing operating costs.

Participants will gain insight into multiphase flow behavior, fluid characterization, and the thermal, chemical, and mechanical control methods used to prevent flow restrictions. The course also explores design considerations for flowlines and pipelines, and highlights the use of modeling tools and field data for performance prediction and troubleshooting.

Through a balance of theory and practical case studies, this program equips professionals to develop integrated flow assurance strategies that align with operational and economic goals.

As oil and gas developments move into deeper waters and more complex environments, ensuring reliable hydrocarbon flow has become increasingly challenging. Flow assurance involves the anticipation and management of potential production issues—from hydrate formation and wax deposition to scale buildup and corrosion.

This course introduces participants to the scientific principles and practical approaches that underpin flow assurance. It emphasizes understanding the interactions between fluid properties, operating conditions, and transport systems to maintain continuous and efficient flow throughout the production lifecycle.

By the end of this course, participants will be able to:

-

Understand the key principles of flow assurance and its role in field development and production.

-

Identify common flow assurance challenges such as hydrates, wax, asphaltenes, and scale.

-

Apply thermal, chemical, and mechanical methods for flow assurance management.

-

Analyze multiphase flow behavior in subsea and surface systems.

-

Utilize modeling tools to predict flow behavior and optimize system design.

-

Evaluate case studies and develop effective mitigation and remediation strategies.

The course combines interactive lectures, illustrative case studies, group problem-solving sessions, and practical examples drawn from real field operations. Simulation tools and flow assurance modeling concepts are discussed to help participants connect theory to actual design and troubleshooting scenarios. The learning environment encourages discussion and knowledge sharing among participants from different disciplines.

By applying the principles learned in this course, organizations can expect to:

-

Reduce production losses caused by flow blockages or system failures.

-

Improve design reliability and operational efficiency of flow systems.

-

Minimize costly intervention and maintenance activities.

-

Strengthen cross-disciplinary collaboration between production, process, and pipeline teams.

-

Enhance safety and environmental performance through proactive flow management.

Participants will gain:

-

A solid foundation in flow assurance principles and field applications.

-

The ability to diagnose, analyze, and mitigate flow-related issues.

-

Improved understanding of multiphase flow and its operational implications.

-

Practical exposure to modeling tools and industry best practices.

-

Greater confidence in making data-driven flow assurance decisions.

This course is designed for professionals involved in production, flow assurance, and system design, including:

-

Flow Assurance and Production Engineers\

-

Process and Facilities Engineers

-

Subsea and Pipeline Engineers

-

Field Development and Operations Personnel

-

Reservoir and Petroleum Engineers

-

Project Managers and Technical Advisors

Module 1:

Introduction to flow assurance.

Introduction to Production Systems.

Basics of Steady State Modeling.

Boundary and Initial Conditions

Basics of Transient Modeling.

Introduction to Results,Outputs, Reports, Plotting

Module 2:

Introduction to Oil and Gas Field Fluids.

Working With Oil and Gas Field Fluids.

Black Oil Modeling.

Compositional Modeling

Solid Phase Modeling.

Single phase Modeling.

Drilling/Completion Modeling.

Module 3:

Introduction to CO2 Corrosion.

Introduction to CO2 Corrosion Modeling.

Introduction to Flow Patterns.

Introduction to Slugging.

Modeling Slugging in Pipelines.

Introduction to WAX Problems.

Modeling Wax in Surface Connections

Module 4:

Introduction to troublesome Field Operation.

Introduction to system shut-ins.

Pipelines Cool downs.

Pipeline Blowdown.

Heat transfer between pipes and surroundings.

Design of Piping Segments.

Module 5:

Working with Oil and Gas Wells.

Introduction to IPR.

Time Dependent Factors in IPR Modeling.

Working with Depleted Reservoirs.

High Water Cut wells and hydraulic calculations.

Liquid accumulation in Gas wells.

On successful completion of this training course, PEA Certificate will be awarded to the delegates.

Mr. Nashat J. Omar With over 12+ years of specialized experience in petroleum engineering, focus on production and flow assurance brings valuable expertise to the energy sector.

He possess a strong command of Python and C#, which empowers him to create efficient data management solutions and streamline workflows.

His collaborative nature and adaptability enable him to thrive in multidisciplinary settings, where he consistently contributes to success through innovative problem-solving.

He is dedicated to continuous learning and staying ahead of industry advancements, ensuring that he can enhance operational efficiency and guarantee robust flow assurance.

Frequently Asked Questions

All course bookings made through PEA are strictly non-refundable. By registering for a course, you acknowledge and accept that all fees are payable in full and are not subject to refund under any circumstances, including changes in personal or professional commitments or partial attendance.

PEA reserves the right to make reasonable adjustments to course content, trainers, or schedules where necessary, without entitling delegates to a refund. Comprehensive details of each course — including objectives, target audience, and content — are clearly outlined before enrolment, and it is the responsibility of the delegate to ensure the course's suitability prior to booking.

For any inquiries related to cancellations or bookings, please contact our support team, who will be happy to assist you.