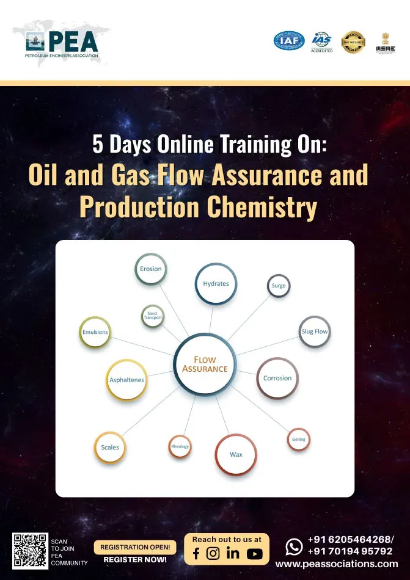

Oil and Gas Flow Assurance and Production Chemistry

| Code | Date | Time | Duration | Location | Currency | Team of 10 Per Person | Team of 7 Per Person | Early Bird Fee Per Person | Normal Fee Per Person |

|---|---|---|---|---|---|---|---|---|---|

| PEA/FAP/26 | 03 - 07 Aug 2026 | 9 PM Indian Time |

4 Hours Per Day

|

Zoom Online

|

USD

|

1500

|

1850

|

2000

|

2500

|

Boost your team's skills and your budget! Enjoy group discounts for collaborative learning. Send an inquiry to info@peassociations.com.

Oil and Gas Flow Assurance and Production Chemistry

This course provides a comprehensive understanding of flow assurance and production chemistry, emphasizing techniques to mitigate flow-related issues and enhance operational efficiency in oil and gas production. Through expert-led instruction, participants will gain insights into practical solutions for real-world challenges in flow assurance and production chemistry.

Description

In the Oil and Gas Flow Assurance and Production Chemistry course, participants will learn critical strategies to address flow assurance challenges and production chemistry concerns. The course covers topics like hydrates, asphaltenes, wax deposition, corrosion, scale management, and more. Attendees will develop the skills necessary to prevent and resolve flow disruptions, ensuring optimal production and operational continuity. Using real-world examples, case studies, and interactive sessions, the course prepares participants to make informed decisions in flow assurance and production chemistry.

Demo Class

Flow assurance and production chemistry are vital for maintaining the uninterrupted, safe, and efficient operation of oil and gas production systems. This course delves into the chemistry and engineering solutions required to address challenges such as blockages, corrosion, and other flow-related issues that can impact production. Through a balanced mix of theory and practical application, participants will gain the expertise to diagnose and mitigate these issues effectively.

Acquire a comprehensive understanding of the fundamental principles of flow assurance.

Identify the main flow assurance and production chemistry issues.

Understand fluids equilibrium during production and gain the key practical skills for fluids sampling, analysis, and their methodologies.

Gain practical skills in modeling and simulation.

Gain the key skills to conduct robust risk assessment, implement effective treatment, and process monitoring.

Gain essential skills in lab and process integration

and data management.

This course employs a blend of interactive lectures, case studies, group discussions, and practical exercises. Participants will gain hands-on experience in identifying and addressing flow assurance issues through simulations and real-world problem-solving techniques.

Reducing downtime and maintenance costs through effective flow assurance practices.

Enhancing production efficiency and minimizing operational risks.

Practical knowledge of flow assurance and production chemistry techniques.

Production technicians

OIMs, Supervisors, and area managers

Production engineers

Reservoir engineers

Account managers

Production chemists

Lab chemists

Microbiologists

Corrosion engineers

Students and interns

Day 1:

Introduction to Flow Assurance & Scale Management

Introduction to flow assurance and production chemistry

Overview of oil and gas production systems

Understanding production fluids and phase equilibrium

Concept and importance of flow assurance in oil and gas systems

Fluids hydrodynamics and multiphase flow problems

Origins of production chemistry problems

Mineral scales: formation, types, mechanisms, and impact on operations

Scale risk assessment, analysis, prediction, and monitoring methods

Scale mitigation: operational, chemical (inhibitors), non-chemical, and removal methods

Designing and implementing an efficient scale management strategy

Case studies on wax, asphaltenes, emulsions, corrosion, gas hydrates, MIC, biofouling, sand production, and slugging

Day 2:

Gas Hydrates, Wax, and Asphaltenes

Gas hydrates: formation mechanisms, risk factors, and operational impacts

GH prediction, monitoring, prevention, and removal methods (chemical and operational)

Designing effective GH management strategies and case studies

Wax problems: crude oil composition, gelation, deposition mechanisms, and risk assessment

Fluids testing, prediction, deposits analysis, and monitoring

Wax mitigation: operational, chemical, and non-chemical methods

Wax removal and management strategy design with case studies

Asphaltenes: composition, properties, aggregation, and deposition

Risk assessment and testing methodologies

Asphaltene mitigation: operational, chemical, and non-chemical methods

Designing effective asphaltene management plans with case studies

Day 3:

Emulsions, Crude Dehydration & Soaps

Emulsion formation, types, and influencing factors

Crude oil dehydration processes and equipment

Chemical demulsifiers: selection, testing, and field monitoring

Reverse emulsion mitigation and sludge management

Foam problems and mitigation in oilfields

Gas dehydration: absorption, adsorption, and condensation methods

TEG dehydration and common operational issues

Naphthenate and carboxylate soaps formation and impact

Soap emulsions versus scales

Testing, prediction, and mitigation of soap-related problems

Designing effective soap mitigation strategies and case studies

Day 4:

Corrosion, MIC & H₂S Management

Corrosion mechanisms, types, and cost implications

Risk assessment, monitoring, and management

Corrosion prevention: system design, materials, coatings, inhibitors, and cathodic protection

Case studies on corrosion control

Oilfield microbiology: microorganisms’ impact on production

MIC (Microbiologically Influenced Corrosion) and biofouling control

Reservoir souring and microbial detection/monitoring techniques

Microorganisms management using operational, chemical, and non-chemical methods

Case studies on microbial issues and Microbial Enhanced Oil Recovery (MEOR)

H₂S management: origins, impacts, measurement, and mitigation methods

Day 5:

Sand Production, Water Treatment & Field Monitoring

Causes and management of sand production in wells

Water injection and produced water treatment processes

Water quality control and testing methods

Overview of production chemicals: types, tendering, and applications

Chemical management strategies for efficiency

Carbon Capture, Utilization, and Storage (CCUS): CO₂ capture, transport, and storage

Oilfield process monitoring and chemical analysis methods

Production monitoring tools: sensors, pigging, ILI, and smart robotics

Laboratory sessions: crude oil, water, solids, microbiological, lube oil, and production chemical analyses

On successful completion of this training course, PEA Certificate will be awarded to the delegatesA

Abdullah Hussein: An Experienced oil and gas production chemistry expert with 16+ years of expertise in chemical lab operations, crude oil processing, water treatment, and solving complex production chemistry challenges, including emulsions, scale deposits, and corrosion.

Published author of "Essentials of Flow Assurance Solids in Oil and Gas Operations," a comprehensive guide on flow assurance in the oil and gas industry.

Founder of Chemdustry (Canada), providing specialized training and consulting services for production chemistry and flow assurance, with over 230 trainees globally and 56 training courses delivered.

Successfully supported 10+ oil and gas companies through online consultations, resolving 40+ field cases and fostering operations across regions like North and South America, Europe, the Middle East, and Africa.

Frequently Asked Questions

All course bookings made through PEA are strictly non-refundable. By registering for a course, you acknowledge and accept that all fees are payable in full and are not subject to refund under any circumstances, including changes in personal or professional commitments or partial attendance.

PEA reserves the right to make reasonable adjustments to course content, trainers, or schedules where necessary, without entitling delegates to a refund. Comprehensive details of each course — including objectives, target audience, and content — are clearly outlined before enrolment, and it is the responsibility of the delegate to ensure the course's suitability prior to booking.

For any inquiries related to cancellations or bookings, please contact our support team, who will be happy to assist you.