Well Stimulation and Acidizing

Stimulation is a term used to describe different operation carried out in an oil well to get optimum productivity.

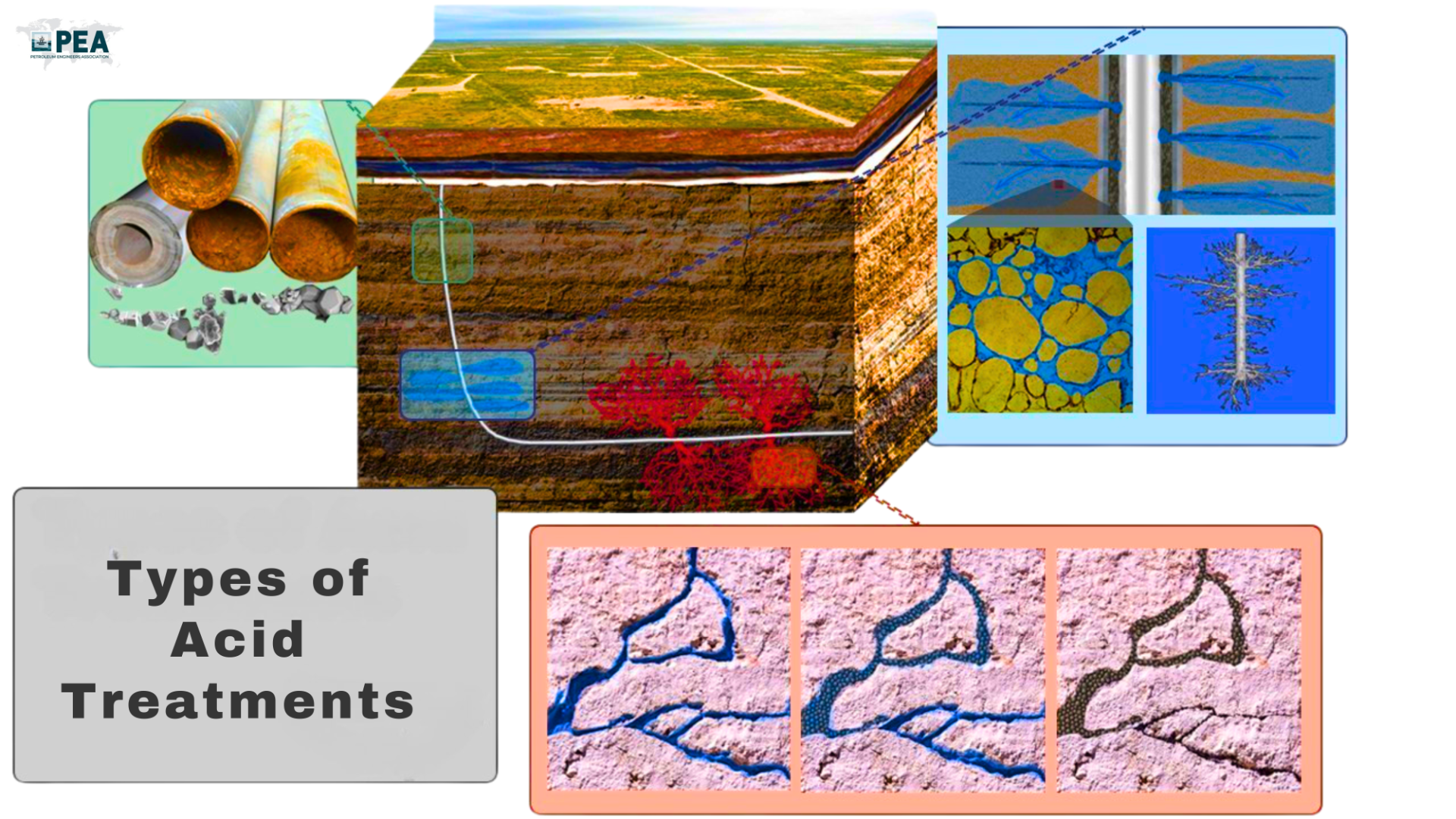

Lets discuss various types of acid treatments.

(1) Acid washing – Here our goal is wellbore cleaning

(2) Matrix acidizing – Here we are injecting acid in the reservoir, but we do it at so-called matrix pressures, or simply at pressures below formation fracturing pressure.

(3) Fracture acidizing treatment – Here we inject acid at pressures above formation fracturing pressure.

The first type of acid treatment we will talk about can be called “Acid Washing”. Here, we inject acid and keep this acid inside the tubulars. It is important to point out that we do not intend formation treatment.

Our objective during acid washing is tubular and wellbore cleaning. Normally, we are removing inorganic scale, rust, and other debris that negatively impacts production, and restricts the flow in the well.

In this case, we inject acid through the perforations in the formation. Injection pressure is below fracturing pressure. Our goal here is to improve permeability in the near-wellbore region. The way we reach this goal would depend on the reservoir mineralogy.

For example, in a sandstone reservoir – our goal is to remove the damaging material. It can be certain minerals or other solid particles and fines that are blocking pore throats and pore spaces between grains of sand. Acid is injected to flow through the pore network and dissolve these materials that plug the porous media.

And in a carbonate formation, our goal is to bypass the damaged zone. We do this by dissolving rock and creating these channels, called wormholes. To form these branches and channels, we have to choose the right acid and injection rate, but ultimately, we want to extend these wormholes from perforations beyond the near-wellbore zone. This would create a conductive pathway for our hydrocarbons to flow through.

In this treatment, acid is intentionally pumped at a pressure above formation fracturing pressure. Such treatments are primarily used in carbonates.

We bypass the formation damage and stimulate the undamaged formation at the same time.

This technique is an alternative to both matrix acidizing and hydraulic fracturing. In a way, our objective is similar to these traditional techniques because we want to maximize the stimulated reservoir volume.

Therefore, we create long, open, conductive channels from the wellbore, extending deeper into the formation. However, there is a big difference from traditional hydraulic fracturing – and this difference is about the way we create and maintain fracture conductivity.

First, we pump acid or some viscous fluid to raise the pressure and open the fracture. But remember that if we stop the injection – pressure will drop down and fracture will close. Therefore, traditionally before releasing the pressure, we prop the fracture with sand or similar material called proppant, to keep the fracture open, and maintain its conductivity.

Often times there would be some fracture wings that we can’t effectively pack with proppant. And once pressure is released, the fracture will close. If proppant was placed in the fracture then conductivity will be maintained to be high, and if there is no proppant then we might lose that conductive pathway because the fracture will be completely shut.

But in acid fracturing, once acid travels down the fracture – it dissolves the walls of the fracture. If this dissolution is nonuniform, then the fracture may close with conductivity retained even if there is no proppant in it. This is due to the fact that there would be high and low spots, or in other words voids and points of support, and they will hold the channel open and flowable. So, this is the main idea behind acid fracturing.

Leave a comment on this Blog/Article.