Formation Damage: Causes and Prevention During Production

Formation damage is one of the most common and costly problems in oil and gas production. It silently reduces a reservoir’s ability to produce hydrocarbons efficiently and can lead to significant economic losses if not addressed properly. Understanding its causes and adopting preventive measures are crucial for maintaining well productivity and reservoir performance.

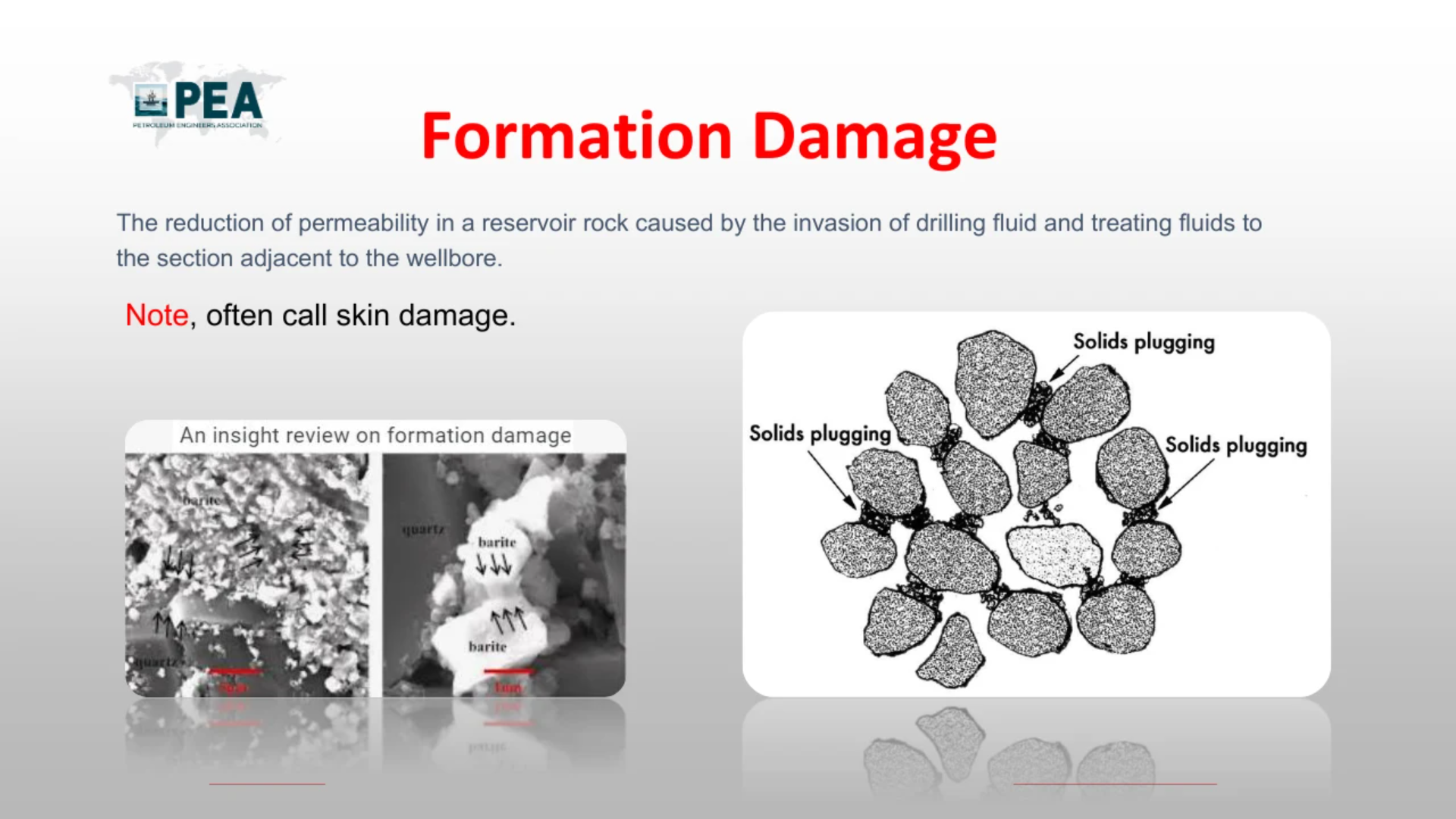

What is Formation Damage?

Formation damage refers to the reduction of a reservoir’s permeability caused by physical, chemical, or biological alterations in the near-wellbore region. In simple terms, it means that the rock’s natural ability to allow oil, gas, or water to flow is reduced. Even a small decrease in permeability can cause a significant drop in production rate. Formation damage can occur during drilling, completion, stimulation, or production, but during the production phase, it often results from the interaction of fluids, solids, and chemical reactions within the reservoir.

Common Causes of Formation Damage During Production

One of the most frequent causes of formation damage during production is fines migration. Fine clay and silt particles detach from pore walls when fluid velocity or flow direction changes. These particles move with the produced fluids and accumulate in pore throats, reducing permeability. Fines migration is especially common in unconsolidated formations or when incompatible fluids alter the salinity balance. Controlling flow rates and stabilizing the formation chemically can reduce this effect.

Another major issue is scale deposition. As pressure, temperature, or water composition changes during production, dissolved minerals such as calcium carbonate, barium sulfate, or strontium sulfate can precipitate as solid deposits. These scales clog pore spaces, perforations, and tubing, leading to reduced productivity. Regular monitoring of water chemistry and using chemical scale inhibitors are effective preventive measures.

Wax and asphaltene deposition is another major cause of formation damage. When temperature or pressure decreases, heavy hydrocarbon components separate from crude oil and solidify near the wellbore or in the tubing. This restricts flow and requires frequent cleaning operations such as hot oiling or solvent washes. Preventing this involves thermal control and the use of dispersants or inhibitors.

Water blockage is another common issue, particularly in gas wells. Water-based fluids can become trapped in the formation, reducing gas relative permeability and creating a barrier to flow. Surfactant-based treatments can help remove trapped water and restore production.

Emulsion formation and wettability alteration can also cause serious flow problems. Oil-water emulsions, created by turbulence or incompatible fluids, can plug pore spaces. When the rock surface changes from water-wet to oil-wet, the flow of hydrocarbons becomes more difficult. Maintaining fluid compatibility and using demulsifiers are key solutions.

Corrosion by-products and bacterial growth further contribute to formation damage. Corrosion can generate solids like iron sulfide or oxides that block flow paths, while bacteria such as sulfate-reducing species create biofilms and hydrogen sulfide. Routine biocide and corrosion inhibitor treatments are essential to prevent such damage.

Conclusion

Formation damage can significantly reduce a well’s productivity and increase operating costs if not managed properly. By understanding the main causes such as fines migration, scale, wax, emulsions, and water blockages, production engineers can take preventive actions to protect the reservoir. Continuous monitoring, chemical control, and careful production management are vital to minimizing formation damage and ensuring long-term reservoir performance.

Leave a comment on this Blog/Article.