Extended Reach Drilling Wells

Imagine drilling not just down but miles across the earth, reaching oil and gas reserves far beyond what was once thought possible.

That’s the power of Extended-Reach Drilling (ERD), one of the most groundbreaking achievements in modern petroleum engineering.

Let’s explore

In the early days, drilling straight down was the only way to reach hydrocarbons. But as easy reservoirs were depleted, engineers faced a new challenge how to access resources hidden beneath restricted zones or complex terrains.

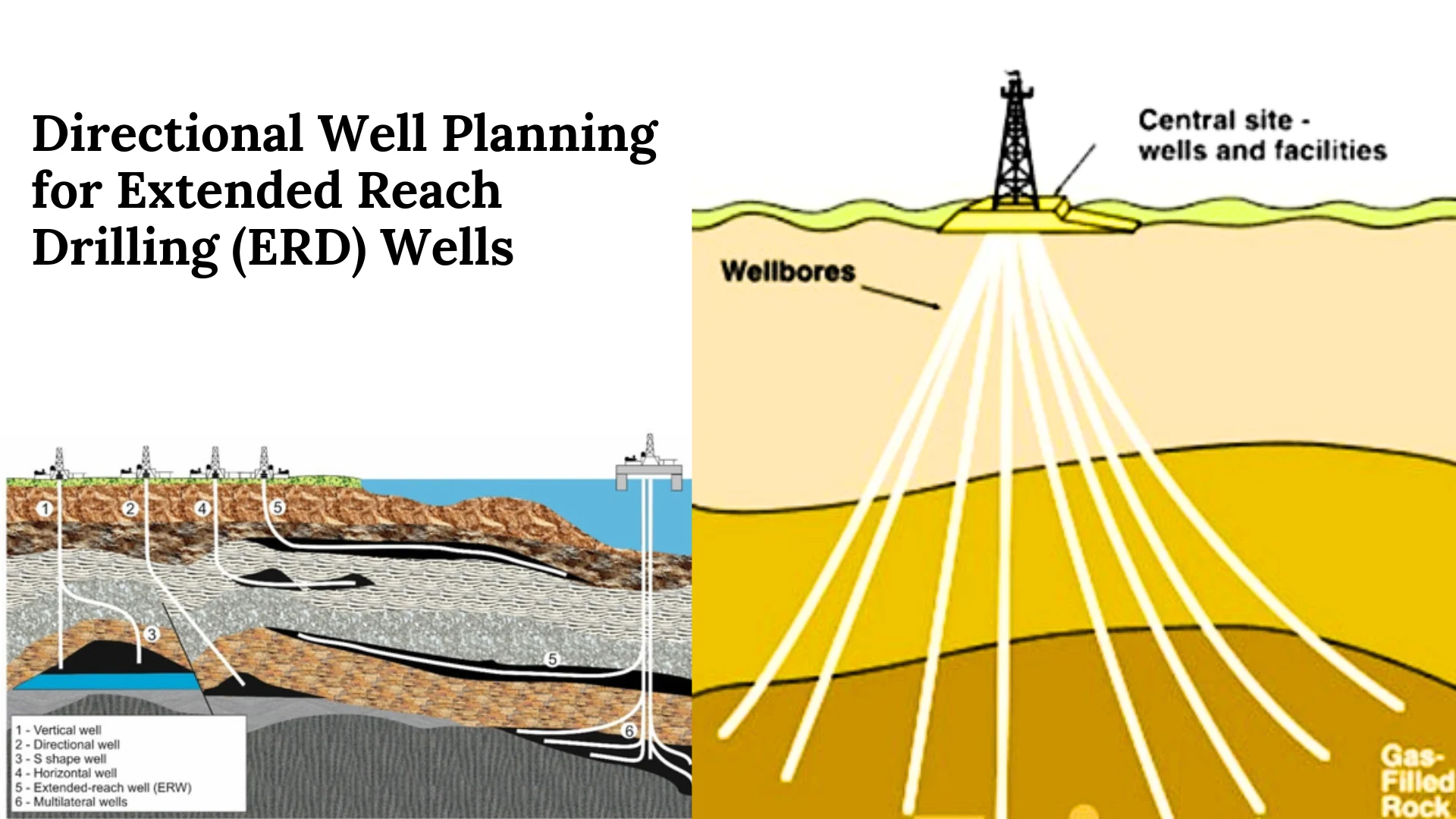

That challenge gave birth to directional drilling, and later, to extended-reach drilling (ERD) a technique that combines horizontal and directional drilling to reach targets located several kilometers away from the well site.

An ERD well is defined as one where the horizontal reach is more than twice the true vertical depth (TVD) or exceeds 6,000 meters in displacement.

Today, we even talk about ultra-extended-reach wells, with operators continuously pushing the limits of engineering and physics.

Why ERD Changed Everything

Extended-Reach Drilling is not just a technical evolution — it’s a smarter, cleaner, and more economical way to produce energy.

Higher Production: A single ERD well can contact multiple reservoir sections, significantly increasing hydrocarbon recovery.

Lower Environmental Footprint: Fewer surface locations mean less land disturbance — ideal for offshore and onshore projects in sensitive zones.

Cost Efficiency: By reaching multiple targets from one pad, operators reduce infrastructure and drilling costs.

In short, ERD allows the industry to do more with less — more production, less impact.

Here’s what makes ERD such a demanding art and science:

Torque and Drag: As the wellbore extends horizontally, friction between the drill string and wellbore walls increases, often pushing tools and materials to their physical limits.

Hole Cleaning: Removing rock cuttings efficiently is harder in long horizontal sections. Poor hole cleaning can cause stuck pipe or reduced drilling efficiency.

Equivalent Circulating Density (ECD): Managing pressure along extended wellbores is critical to prevent formation fractures or mud losses.

Barite Sag: Long static periods or slow flow rates can lead to uneven mud weight and wellbore instability.

Each of these challenges demands real-time monitoring, smart fluid design, and constant operational adjustment.

The Secret Hero: Drilling Fluids

Behind every successful ERD operation is the right drilling fluid the unsung hero of well control and efficiency.

Modern ERD wells rely heavily on oil-based muds (OBMs) and synthetic-based muds (SBMs) due to their superior lubricity, stability, and hole-cleaning properties.

However, the industry is also moving toward advanced water-based muds (WBMs) enhanced with polymers, fibers, nanoparticles, and eco-friendly additives offering both technical performance and environmental responsibility.

The right fluid ensures smoother torque and drag performance, better hole cleaning, and safer drilling at extreme depths.

🔬 Technology Behind the Precision

What keeps an ERD operation precise and efficient is the combination of innovation and data:

- Rotary Steerable Systems (RSS): Provide continuous rotation with pinpoint directional control.

- Real-Time Data Telemetry: Transmits downhole data via mud pulse or electromagnetic systems to optimize decisions instantly.

- Mechanical Hole-Cleaning Tools (Hydroclean): Create turbulence and remove debris more efficiently.

- Machine Learning Models: Predict torque, drag, and hole-cleaning performance transforming drilling into a data-driven science.

These technologies together form the backbone of modern digital drilling operations, paving the way for automation and predictive control.

Leave a comment on this Blog/Article.