Directional Drilling Practices and Applications

In the ever-evolving landscape of the oil and gas industry, directional drilling has emerged as a critical technology, enabling companies to reach new depths (literally!) and maximize resource recovery.

Let's explore how directional drilling is reshaping the industry and driving efficiency.

Why Directional Drilling Matters in Oil & Gas 💡

Traditional vertical drilling often limits access to hydrocarbon reserves, especially those located in challenging geological formations or beneath sensitive environmental areas.

Directional drilling overcomes these limitations by:

Unlocking Unconventional Resources: Tap into shale oil and gas plays, tight sands, and coalbed methane reservoirs that were previously inaccessible.

Maximizing Reservoir Contact: Extend wellbores horizontally or multilaterally to increase exposure to productive zones, boosting production rates and ultimate recovery.

Reducing Environmental Footprint: Minimize surface disturbance by drilling multiple wells from a single pad, reducing land use and ecological impact.

Overcoming Obstacles: Navigate around geological faults, salt domes, and other subsurface challenges to reach target zones efficiently.

Key Applications in Oil & Gas ⚙️:

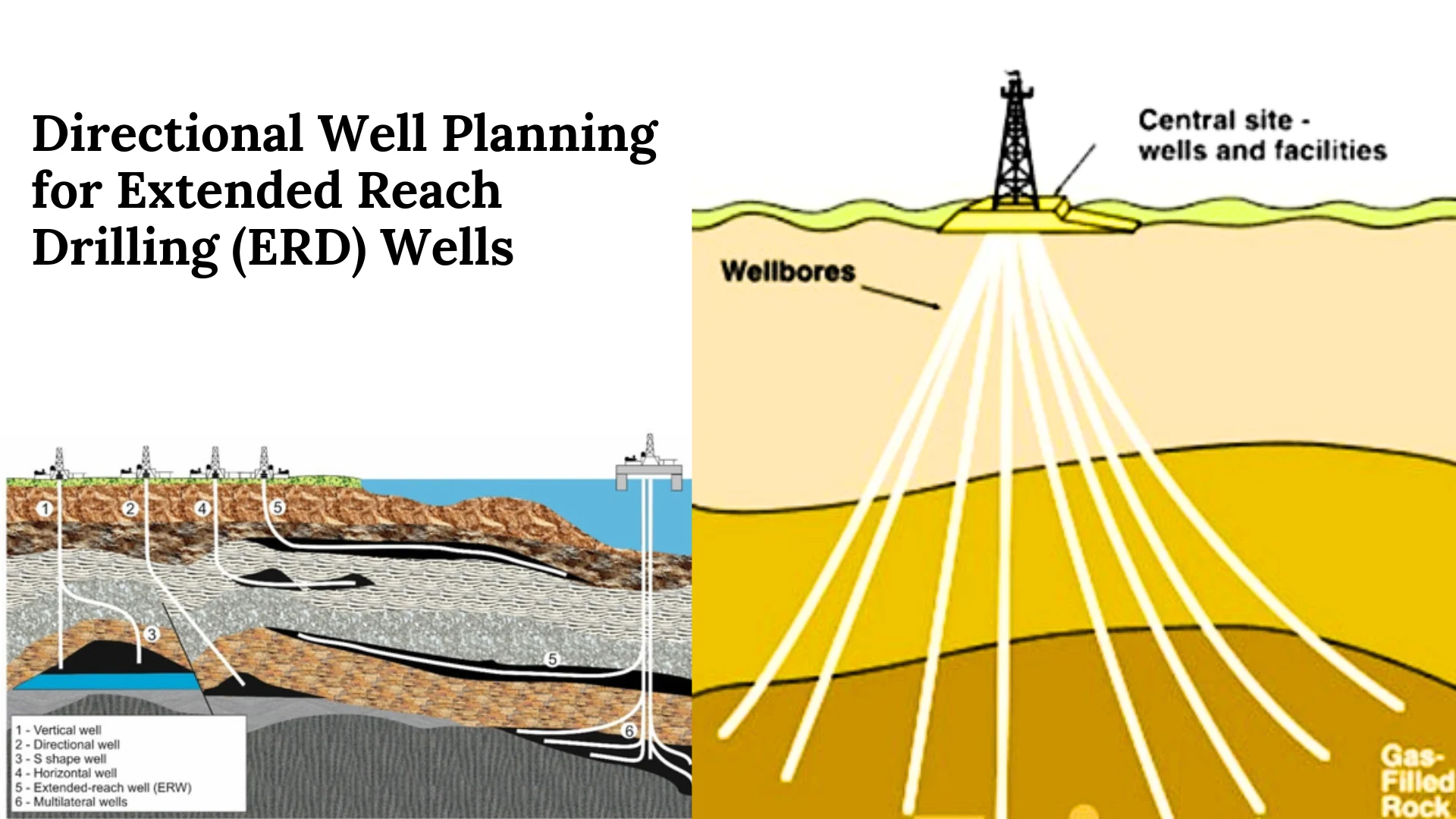

Offshore Drilling: Reach reservoirs far from platforms, reducing the need for multiple installations and minimizing costs.

Extended Reach Wells: Access reserves located miles away from the drilling rig, enabling development of fields in remote or challenging locations.

Multilateral Wells: Drill multiple branches from a single wellbore to maximize reservoir contact and optimize production.

Horizontal Wells: Drill horizontally through productive zones to increase exposure and improve recovery rates.

Technological Advancements Driving Efficiency 🚀:

Rotary Steerable Systems: Achieve precise wellbore placement with real-time control and adjustments.

Measurement-While-Drilling (MWD) and Logging-While-Drilling (LWD): Gather crucial subsurface data during drilling operations, optimizing well trajectory and reservoir characterization.

Geosteering: Utilize real-time geological data to navigate through complex formations and stay within the target zone.

Automation and Robotics: Enhance drilling efficiency and safety with automated systems and robotic drilling rigs.

The Future of Directional Drilling in Oil & Gas 🔮:

As the industry continues to push boundaries, directional drilling will play an even greater role in:

Enhancing Recovery Rates: Develop innovative techniques to extract more hydrocarbons from existing fields.

Reducing Costs: Optimize drilling operations through automation, data analytics, and improved drilling practices.

Minimizing Environmental Impact: Develop sustainable drilling technologies and practices to protect ecosystems and reduce emissions.

To learn more: https://www.peassociations.com/e-learning-coursedetails/directional-drilling-practices-and-applications

Leave a comment on this Blog/Article.