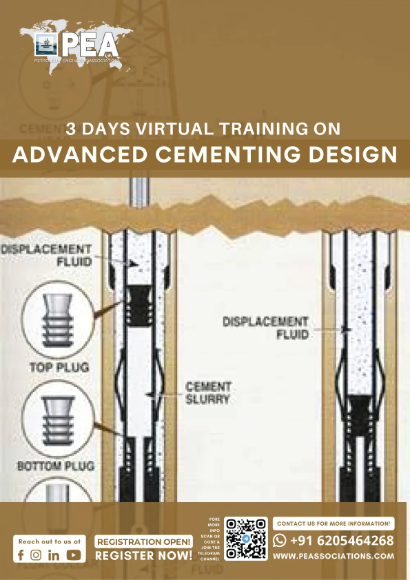

Advanced Cementing Design

Have Questions ?

Advanced Cementing Design - PEA-DL-ACD26

| Code | Date | Time | Duration | Location | Currency | Team of 10 Per Person | Team of 7 Per Person | Early Bird Fee Per Person | Normal Fee Per Person |

|---|---|---|---|---|---|---|---|---|---|

| PEA-DL-ACD26 | 18 - 20 May 2026 | 9:30 PM Indian Time |

3 Hours Per Day

|

Zoom Online

|

USD

|

800

|

850

|

1000

|

1250

|

The Classes Will be Online Via Zoom from Monday to Wednesday.

Boost your team's skills and your budget! Enjoy group discounts for collaborative learning. Send an inquiry to info@peassociations.com.

Advanced Cementing Design

This course provides in-depth knowledge of advanced cementing design, covering the principles, materials, and techniques required for reliable zonal isolation and well integrity. Participants will learn how to design and execute cementing programs for complex well conditions using advanced modeling, fluid selection, and placement optimization.

Description

The Advanced Cementing Design course focuses on the engineering aspects of well cementing, emphasizing the design, planning, and evaluation processes that ensure safe and cost-effective well construction. Cementing is one of the most critical operations in drilling and completion—essential for providing well integrity, preventing fluid migration, and maintaining environmental safety.

The course covers advanced topics such as slurry design optimization, cement additives, rheology control, displacement efficiency, and cement evaluation. Participants will also learn about cementing challenges in high-pressure high-temperature (HPHT) wells, deviated and horizontal wells, and wells with complex formations.

Real-world examples and case studies illustrate how modern cementing design techniques, simulation software, and best practices help reduce operational risks and improve well performance throughout the life cycle.

As well designs become more complex and drilling environments more challenging, advanced cementing design plays a vital role in ensuring long-term well integrity. This course introduces the latest design methods and technologies for planning and executing primary, remedial, and specialized cementing operations.

Participants will gain the knowledge and skills to analyze well conditions, select suitable materials, and design cementing programs that meet technical and operational objectives while maintaining safety and efficiency.

Understand the principles of cementing design and zonal isolation.

Evaluate formation characteristics and well conditions for cement design.

Design and optimize slurry systems using additives and laboratory testing data.

Model fluid placement and predict cement displacement efficiency.

Address challenges in HPHT, deviated, and extended reach wells.

Apply advanced techniques for liner, plug, and remedial cementing operations.

Interpret cement bond logs and other evaluation data for quality assurance.

The course combines interactive lectures with design exercises and real project case studies. Participants will engage in problem-solving sessions using design Excel Sheets and laboratory data to evaluate slurry performance and placement outcomes. Group discussions and examples from actual field operations reinforce practical understanding and skill development.

Improved well integrity and reduced risk of cement failures.

Enhanced operational efficiency and cost control in drilling programs.

Increased capability to design and execute cementing for complex wells.

Strengthened safety, reliability, and environmental performance.

Better integration between drilling, completion, and cementing teams.

Strengthen technical knowledge in cementing design and applications.

Develop confidence in analyzing and solving cementing challenges.

Improve career prospects in drilling, completion, and well integrity management.

Enhance decision-making and technical communication skills.

Drilling Engineers and Supervisors

Cementing and Completion Engineers

Well Integrity and Operations Engineers

Service Company Specialists involved in cementing operations

Technical Managers overseeing well construction projects

Introduction to Primary & Remedial Cementing

Objectives of Well Cementing

Characterization of API Cements

Cement Additives and Functions

Laboratory Testing, Equipment & Procedures

Rheology of Cementing Slurries

Flow Regimes & Mud Removal

Cement Spacers

Centralization & Pipe Movement

Cement Placement Simulators

Mechanical Properties of Well Cements

Cement Integrity Simulators

Formation Fluid Migration Prevention

Cementing for High Pressure and High

Temperature (HPHT) Applications

Cementing for Deepwater Applications

Cementing for Horizontal Well Applications

Loss Circulation Prevention while Cementing

Cementing Equipment and Casing Hardware

Cementing Calculations

Cement Job QA/QC and Evaluation

Cement Bond Log Interpretation

Plug Cementing

Squeeze Cementing

On successful completion of this training course, PEA Certificate will be awarded to the delegates.

Your expert course instructor, based in the Netherlands, is a seasoned petroleum engineer specializing in advanced cementing techniques with over 25 years of hands-on experience in drilling operations, cement design innovation, and well construction across global oil and gas fields. Since 2015, he has served as a key technical advisor for the Cementing Subcommittee within the Society of Petroleum Engineers (SPE), contributing to industry standards on zonal isolation and HPHT challenges. He has authored or co-authored 25+ technical publications, including chapters on cement slurry optimization and several patents related to gas migration control.

He conducts specialized training on primary and remedial cementing, mud removal strategies, cement bond log analysis, and equipment QA/QC for professionals in drilling, completion, and production roles worldwide. His research focuses on simulators for cement placement, mechanical properties under extreme conditions, and loss circulation prevention in deepwater and horizontal wells.

He brings deep expertise in: cement additives and rheology, laboratory testing procedures, spacers and centralization, HPHT/deepwater cementing, formation fluid migration control, cement job evaluation, plug and squeeze cementing, as well as casing hardware and cementing calculations. With projects spanning North Sea operations, Middle East fields, and Asia-Pacific basins, he has optimized cement designs for complex environments to ensure long-term well integrity.

Frequently Asked Questions

All course bookings made through PEA are strictly non-refundable. By registering for a course, you acknowledge and accept that all fees are payable in full and are not subject to refund under any circumstances, including changes in personal or professional commitments or partial attendance.

PEA reserves the right to make reasonable adjustments to course content, trainers, or schedules where necessary, without entitling delegates to a refund. Comprehensive details of each course — including objectives, target audience, and content — are clearly outlined before enrolment, and it is the responsibility of the delegate to ensure the course's suitability prior to booking.

For any inquiries related to cancellations or bookings, please contact our support team, who will be happy to assist you.