Waterflooding: Boosting Oil Recovery

Introduction to Waterflooding

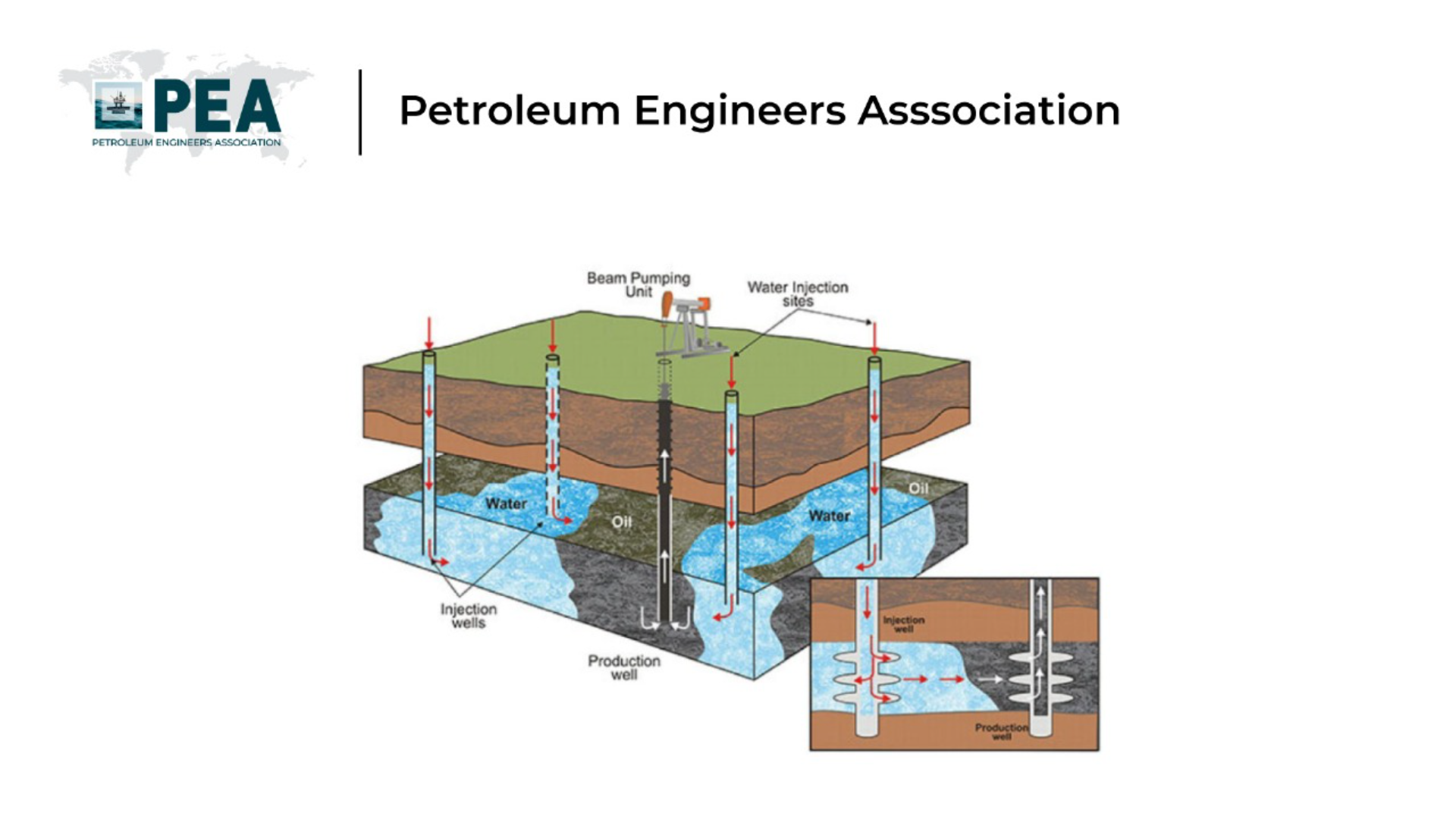

Waterflooding is a cornerstone technique in the oil and gas industry, used to enhance oil recovery from reservoirs. As one of the most common secondary recovery methods, it involves injecting water into an oil reservoir to maintain pressure and push oil toward production wells. This process not only extends the life of mature oil fields but also maximizes the extraction of valuable resources. In this blog, we’ll dive into what waterflooding is, how it works, its benefits, and the challenges it presents.

How Does Waterflooding Work?

Waterflooding operates on a simple yet effective principle: water acts as a sweeping mechanism to displace oil trapped in reservoir rock. After the initial phase of oil production (primary recovery), where natural reservoir pressure drives oil to the surface, pressure often declines, leaving significant amounts of oil behind. Waterflooding steps in as a secondary recovery method to recover more of this remaining oil.

Here’s a quick breakdown of the process:

Injection: Water is injected into the reservoir through dedicated injection wells.

Displacement: The injected water pushes the oil toward production wells, acting like a broom sweeping oil through the porous rock.

Production: Oil, along with some water, is extracted from production wells, increasing overall recovery.

The water used can be sourced from various places, such as seawater, produced water (water extracted alongside oil), or freshwater, depending on availability and compatibility with the reservoir.

Benefits of Waterflooding

Waterflooding has been a game-changer in the oil industry for several reasons:

Increased Recovery: It can boost oil recovery by 10-30% beyond primary recovery, significantly extending the productive life of a field.

Cost-Effectiveness: Compared to advanced methods like chemical or thermal recovery, waterflooding is relatively inexpensive and easier to implement.

Pressure Maintenance: Injecting water helps maintain reservoir pressure, preventing collapse and ensuring steady production.

Versatility: Waterflooding can be applied to a wide range of reservoir types, making it a flexible solution.

Challenges of Waterflooding

While waterflooding is effective, it’s not without its hurdles:

Reservoir Compatibility: The injected water must be compatible with the reservoir’s rock and fluid properties to avoid issues like clay swelling or scaling, which can clog pores and reduce permeability.

Water Sourcing and Treatment: Sourcing large volumes of water and treating it to remove impurities can be logistically and financially demanding.

Uneven Sweep Efficiency: Water may bypass oil in some areas due to reservoir heterogeneity, leaving pockets of oil unrecovered.

Environmental Concerns: Managing produced water, which often contains oil, salts, and chemicals, requires careful handling to minimize environmental impact.

Innovations in Waterflooding

Advancements in technology are addressing some of these challenges. For instance, smart waterflooding involves tweaking the chemical composition of injected water to improve oil displacement. Additionally, advanced reservoir modeling and monitoring techniques, such as 4D seismic imaging, help engineers optimize injection patterns for better sweep efficiency. These innovations are making waterflooding more efficient and sustainable.

Conclusion

Waterflooding remains a vital tool in the oil and gas industry, striking a balance between cost, efficiency, and resource recovery. While it comes with challenges, ongoing innovations continue to refine the process, ensuring it remains relevant in modern oil production. Whether you’re an industry professional or simply curious about energy extraction, understanding waterflooding highlights the ingenuity behind getting more from our planet’s resources.

Interested in learning more about oil recovery techniques? Stay tuned to our blog for deeper insights into the technologies shaping the energy industry!

Leave a comment on this Blog/Article.